Your benefits at a glance

- Higher process speeds while maintaining the same product properties

- Lower formaldehyde emissions at the same process speeds

- Drop-in solution for existing pMDI dosages

- Kauranat can be combined with technological measures

Furniture & Wood

Innovative binding agent raises efficiency of wood-based material production

Kauranat® MS 1001 is BASF’s innovative product for the efficient production of chipboard. This pMDI-based (polymeric diphenylmethane diisocyanate) product works synergistically with amino resins, such as those of the Kaurit® brand. If both binding agents are used together during production, the result is a hybrid system, the curing properties of which enable a significant increase in short press time. This results in increased productivity, without compromising product quality whatsoever.

Amino resins are conventionally used when manufacturing chipboard. It is already known that using hybrid systems consisting of amino resin and pMDI can increase the compression speed by 5 to 10 percent. When using Kauranat® MS 1001 instead of standard pMDI in the hybrid system, this acceleration effect is increased to over 20 percent.

In plants that already use standard pMDI to accelerate the process, Kauranat® MS 1001 can be used as a drop-in solution instead of standard pMDI without the need for any further investment in the infrastructure.

The new hybrid system with Kauranat® cures at a lower temperature than the systems used today, making it particularly well-suited as a binding agent for the middle layer of chipboard, as the temperatures there are lower than in the outer layers during the compression process.

Kauranat® can also be combined with mechanical solutions for faster chipboard manufacturing, such as mat preheating. The higher reactivity of the binding agent system and the more rapid temperature increase during the compression process complement each other.

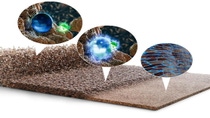

With Kauranat®, BASF has developed a new pMDI-based binding agent type (green), which accelerates curing and thus increases production efficiency when used in combination with Kaurit® glue (blue):

Production with less formaldehyde

Kauranat® makes it possible to manufacture low-emission boards that comply with the CARB2 or even the F4* guidelines. This is because the new binding agent also accelerates production when used together with low-formaldehyde amino resins.

A binding agent with a long tradition

BASF has been selling binding agents for wood-based material production for a long time. Long-standing cooperative business relationships with the timber industry and joint research initiatives with established research institutes play a decisive role in the continuous improvement of the products. The development of Kauranat® MS 1001 was the result of our in-house expertise in the Kaurit® (amino resin) and Lupranat® (pMDI) binding agents.

Kauranat® MS 1001 makes an important contribution to efficient and low-emission production in the timber industry thanks to its universal and simple deployment.