Kaurit® Light – the new lightness

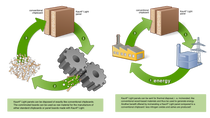

Particleboards are extremely versatile and strong. Unfortunately, they are also rather heavy. For a long time, scientists have been looking for a real light-weight alternative. However, lightweight solutions introduced so far always had disadvantages with regard to the panel’s manufacturing or processing. Particleboards are produced with the new Kaurit® Light-technology weigh 30% less, while being produced and manufactured on existing facilities. Thus, the Kaurit® Light-system is a real and really light alternative.